Nonstick pans with Teflon or similar coatings are generally safe when used correctly, as they’re made from stable materials like PTFE, which resist reactions during normal use. However, overheating beyond recommended temperatures can release fumes harmful to your health and pets. Proper maintenance and cautious use extend their lifespan and safety. To understand how modern innovations improve durability and safety, and why proper use matters, keep exploring the details ahead.

Key Takeaways

- Teflon coatings made from PTFE are generally safe during normal cooking when used at appropriate temperatures.

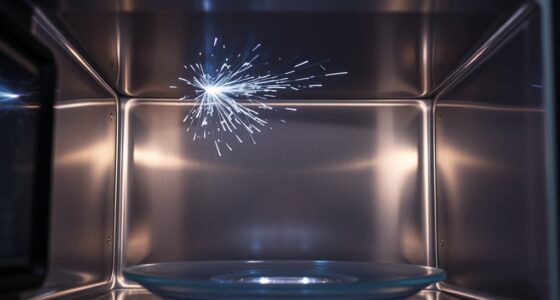

- Overheating nonstick pans above 500°F can release fumes causing flu-like symptoms and harm pets.

- Proper application, curing, and maintenance extend coating lifespan and reduce the risk of particle ingestion.

- PFOA, a chemical once used in manufacturing, has been phased out, making modern nonstick coatings safer.

- Advances in eco-friendly and self-healing coatings aim to improve safety, durability, and environmental impact of nonstick cookware.

What Are Teflon and Nonstick Coatings?

Teflon is a popular brand name for a type of nonstick coating made from a chemical called polytetrafluoroethylene (PTFE). This coating gives your pans a smooth, nonstick surface, making cooking and cleaning easier. When it comes to chemical safety, PTFE is stable at normal cooking temperatures, but overheating can release fumes that may cause flu-like symptoms in humans and harm pet birds. As for environmental impact, Teflon manufacturing involves chemicals that can be harmful if not managed properly, leading to concerns about pollution and persistence in ecosystems. While PTFE itself is generally considered safe during typical use, it’s crucial to avoid overheating your nonstick pans to prevent the release of potentially harmful substances. Proper handling ensures safety for both you and the environment. Additionally, understanding the environmental impact of nonstick coatings can help consumers make more informed choices about their cookware. It is also important to consider the long-term environmental effects associated with the production and disposal of these coatings. Being aware of credit card safety practices can further reduce risks when making online purchases related to kitchen equipment. Moreover, ongoing research into sustainable manufacturing methods aims to reduce environmental footprints associated with nonstick coatings. Staying informed about eco-friendly alternatives can also help consumers choose safer, more sustainable cookware options.

The History and Development of Nonstick Technology

You might be surprised to learn how early experiments with nonstick surfaces began long before modern cookware. Teflon’s invention came from a groundbreaking process that transformed industrial chemistry, leading to its widespread use. Since then, technological advancements have continuously improved nonstick coatings, making them safer and more durable. Additionally, ongoing research into material safety ensures that newer coatings are designed to minimize health risks. For example, scientists are exploring nonstick coating innovations to develop safer alternatives with enhanced performance and environmental compatibility. Moreover, advancements in coating durability aim to extend the lifespan of nonstick pans and reduce the need for replacement.

Early Nonstick Discoveries

The development of nonstick cookware began with early experiments aimed at creating surfaces that repel food and reduce cleanup time. During these culinary experiments, inventors focused on improving kitchen aesthetics while making cooking easier. The first nonstick surfaces were often made from materials like aluminum coated with substances that prevented food from sticking. These innovations aimed to enhance both functionality and visual appeal in the kitchen. Over time, researchers refined these coatings, leading to the development of more durable and effective nonstick layers. Understanding these early discoveries helps you appreciate how far nonstick technology has come. Here’s a quick overview of early nonstick innovations:

| Year | Key Development |

|---|---|

| 1938 | Introduction of Teflon coating |

| 1950s | Commercial use in cookware |

| 1960s | Improvements in durability and safety |

Additionally, ongoing research into appliance safety continues to inform improvements in nonstick coatings and their applications, highlighting the importance of nonstick coating safety in modern cookware design.

Teflon’s Inventive Process

Understanding how nonstick coatings like Teflon were invented involves exploring a series of innovative steps and scientific discoveries. Initially, researchers aimed to develop materials that would resist sticking without relying on harsh chemicals. Teflon’s invention in the 1930s resulted from experimenting with eco friendly materials, leading to the discovery of polytetrafluoroethylene (PTFE). Manufacturing innovations played a pivotal role in refining the production process, making Teflon coatings more durable and uniform. These advancements allowed for scalable manufacturing while reducing environmental impact. As scientists worked to improve the process, they focused on creating a coating that was both effective and safer. This inventive process set the foundation for modern nonstick technology, blending scientific ingenuity with eco conscious practices.

Technological Advancements

Advances in nonstick technology have built upon the discoveries made during Teflon’s invention, leading to more durable and versatile coatings. Modern developments focus on enhancing coating durability, so pans last longer and resist scratches better. Manufacturers now incorporate new materials, like ceramic or reinforced composites, to improve performance. These innovations reduce the risk of coating degradation over time, making nonstick surfaces more reliable. Additionally, ongoing research into coating durability aims to further extend the lifespan of nonstick cookware. As a result, newer coatings are designed to withstand everyday wear and tear more effectively. The incorporation of advanced materials has also contributed to improved resistance against corrosion and chemical degradation. Furthermore, efforts to minimize chemical emissions during manufacturing are part of these technological improvements, aiming for safer cookware options. The development of safer manufacturing processes also helps reduce environmental impact and potential health risks. However, these advancements often come with increased manufacturing costs, which can affect the final price of the cookware. Despite higher costs, consumers benefit from safer, longer-lasting nonstick pans. Overall, technological progress continues to improve nonstick coatings, balancing durability and cost-efficiency, and ensuring users enjoy safer, more durable cookware options.

How Nonstick Coatings Are Made and Applied

You’ll find that nonstick coatings are made from specific materials like polytetrafluoroethylene (PTFE) or ceramic compounds. These materials are carefully applied using techniques such as spraying or brushing to make certain of even coverage. Afterward, they undergo curing and quality checks to guarantee durability and safety. Additionally, understanding the thermal behavior of these coatings is essential for safe and effective use during high-heat outdoor cooking. Proper application techniques also play a crucial role in ensuring the longevity and safety of nonstick pans. Recognizing the material properties of these coatings helps consumers understand how they perform under different cooking conditions, especially when exposed to extreme temperatures, which can affect their safety and effectiveness. Moreover, awareness of the thermal stability of these materials can aid in preventing damage caused by rapid temperature changes.

Coating Material Composition

Nonstick coatings are typically made from a polymer called polytetrafluoroethylene (PTFE), which gives the surface its slick, non-restrictive properties. This material boasts excellent chemical stability, meaning it resists reacting with food or chemicals during cooking. The manufacturing process involves applying a layer of PTFE onto cookware, then baking it to form a durable, smooth coating. While PTFE’s chemical stability benefits cookware longevity, concerns about environmental impact arise if manufacturing waste isn’t properly managed. The table below highlights key aspects of coating materials:

| Aspect | Details |

|---|---|

| Composition | Polytetrafluoroethylene (PTFE) |

| Chemical Stability | Resists reacting during cooking |

| Application Method | Coated and baked onto cookware surface |

| Environmental Impact | Waste management is vital during production |

| Safety Concerns | Proper handling reduces health risks |

Additionally, understanding the manufacturing process can help consumers make informed choices about nonstick cookware. Proper handling of the coating materials during production can significantly reduce potential health and environmental risks. Moreover, awareness of the environmental impact associated with manufacturing can encourage more sustainable practices in the industry. It is also important to recognize the testing and certification standards that ensure safety and quality in nonstick coatings.

Application Techniques Used

The process of applying nonstick coatings involves several precise steps to guarantee durability and effectiveness. First, manufacturers prepare the pan’s surface, often using metal finishes to ensure a smooth, clean base. For ceramic coatings, a liquid ceramic mixture is evenly sprayed or brushed onto the cookware, creating a uniform layer. Metal finishes are typically applied through spraying or dipping, followed by a binding process. Once the coatings are applied, they are carefully embedded into the surface, often with techniques like electrostatic spraying for even coverage. This guarantees the ceramic or other nonstick materials adhere firmly. The application process emphasizes consistency, preventing weak spots that could compromise safety or longevity. Proper application techniques are crucial to maximize the nonstick properties and durability of your pans. Additionally, understanding the environmental impact of coatings, such as the use of Teflon, underscores the importance of safe manufacturing practices.

Curing and Quality Control

After the coatings are applied, they undergo a curing process where heat is used to bond the material firmly to the pan’s surface. This step is critical for guaranteeing manufacturing quality, as it solidifies the nonstick layer and enhances durability. During curing, precise temperature controls are essential to prevent defects, bubbles, or uneven coating. Quality control measures are integrated throughout this process, including inspections and testing to verify coating adhesion and uniformity. Proper curing ensures the nonstick surface maintains its integrity during use, reducing the risk of flaking or degradation. Manufacturers follow strict curing protocols to meet safety standards and deliver consistent, high-quality products. This careful process helps ensure your nonstick pan performs reliably and safely over time.

Common Concerns and Health Risks Associated With Teflon

While Teflon-coated pans are popular for their convenience, concerns about their safety have persisted. You should be aware of potential health implications and environmental concerns linked to Teflon. These include:

- Toxic fumes: Overheating Teflon can release fumes that may cause flu-like symptoms in humans, known as “Teflon flu.”

- Degradation: Repeated use and scratches can cause the coating to break down, potentially releasing particles.

- Environmental impact: Manufacturing and disposal of Teflon contribute to pollution, impacting ecosystems.

- Long-term health risks: There’s ongoing debate about whether exposure to PFOA, a chemical used in production, has health implications.

Staying informed helps you weigh convenience against possible health and environmental risks associated with Teflon.

Scientific Research on Teflon Safety

Scientific studies have extensively examined the safety of Teflon, focusing on its chemical composition and potential health effects. Researchers have found that Teflon’s chemical stability remains intact under normal cooking conditions, meaning it doesn’t break down or release harmful substances when used properly. Concerns about chemicals like PFOA have decreased, as many manufacturers have phased out these compounds. From an environmental perspective, Teflon’s production and disposal raised questions due to its persistence and potential pollution. However, current research indicates that, when maintained correctly, nonstick pans pose minimal environmental impact and do not release significant toxins during typical use. Overall, scientific evidence supports that Teflon coatings are safe for everyday cooking, provided you follow recommended guidelines.

Proper Use and Maintenance of Nonstick Pans

To guarantee your nonstick pans last and remain safe to use, it’s essential to follow proper handling and maintenance practices. First, always use low to medium heat to prevent damage to the coating and extend pan longevity. Second, avoid metal utensils; opt for silicone or wooden tools to prevent scratching. Third, clean your pans with gentle techniques—use warm water and non-abrasive sponges, avoiding harsh scrubbers that can compromise the coating. Fourth, store your pans carefully, stacking with a soft cloth or pan protector to prevent scratches. Proper use and cleaning techniques preserve the nonstick surface, ensuring your pans stay safe and effective much longer. Following these steps helps maintain their performance and reduces health risks associated with degraded coatings.

Alternatives to Traditional Nonstick Cookware

If you’re concerned about the safety and durability of traditional nonstick pans, several alternatives can meet your cooking needs without the potential health risks. Eco-friendly alternatives, like cast iron and stainless steel, offer long-lasting options that don’t release harmful chemicals. Ceramic coatings are also a popular choice; they provide a nonstick surface without Teflon’s concerns and are often made from natural materials. These coatings heat evenly and are generally free of toxic substances, making them safer for everyday use. While they may require a bit more maintenance than traditional nonstick pans, ceramic and other eco-friendly options can be just as effective for sautéing, frying, and baking. Exploring these alternatives helps you choose cookware that’s both safe and sustainable.

Tips for Choosing Safe and Durable Cookware

When selecting cookware, prioritizing safety and durability can help you prevent health risks and ensure your investment lasts. To make the best choice, consider these tips:

- Choose materials with low environmental impact, like cast iron or stainless steel, which are eco-friendly and long-lasting.

- Be aware that manufacturing costs can influence durability; higher-quality products often have better coatings and construction.

- Avoid nonstick pans with coatings that contain potentially harmful chemicals, opting instead for ceramic or seasoned pans.

- Check for sturdy construction and even heat distribution, which enhance durability and reduce the need for replacement.

Future Innovations in Nonstick Surface Technology

Advancements in nonstick surface technology are poised to transform cookware, making it safer, more durable, and environmentally friendly. Researchers are focusing on eco friendly materials that reduce environmental impact and improve safety. Nanotechnology innovations are enabling the development of ultra-thin, scratch-resistant coatings that resist wear and tear longer. These new surfaces aim to eliminate toxic chemicals and enhance heat distribution for better cooking performance. Future nonstick pans could feature self-healing properties, repairing minor scratches automatically. The table below highlights some promising innovations:

| Innovation | Benefits | Material Focus |

|---|---|---|

| Eco friendly coatings | Safer for health and environment | Plant-based polymers |

| Nanotech layers | Increased durability and safety | Nanoparticle-infused films |

| Self-healing surfaces | Longer lifespan, reduced waste | Advanced composite materials |

| Sustainable manufacturing | Lower environmental footprint | Eco-conscious production processes |

Frequently Asked Questions

Are There Any Natural or Eco-Friendly Nonstick Coatings Available?

Yes, there are natural nonstick coatings and eco-friendly alternatives available. You can opt for pans with ceramic or mineral-based coatings, which are free from synthetic chemicals and Teflon. These natural nonstick coatings are safer for your health and better for the environment. When shopping, look for products labeled as eco-friendly or ceramic-coated, and you’ll find options that provide effective nonstick performance without the concerns associated with traditional nonstick pans.

How Does High-Temperature Cooking Affect Nonstick Coating Safety?

When you cook at high temperatures, the nonstick coating can undergo thermal degradation, which may release harmful fumes and compromise coating durability. To keep your pan safe, avoid overheating it beyond 500°F, as this can cause the coating to break down faster. Proper use and care help maintain the nonstick surface’s integrity, ensuring it remains safe and effective for longer.

Can Nonstick Pans Be Safely Used in the Oven?

Using nonstick pans in the oven is like trusting a delicate glass sculpture with heat—you need to guarantee oven safety first. Most nonstick pans are oven-safe up to a certain temperature, usually around 350-500°F, but check your manufacturer’s guidelines. The coating durability varies, so avoid exposing it to high heat or broiling, which can damage the coating. Always verify oven compatibility to keep your cookware in top condition.

Do Nonstick Coatings Release Harmful Fumes Over Time?

Yes, nonstick coatings can release harmful fumes over time, especially if they undergo nonstick degradation. When Teflon fumes are released, they can cause flu-like symptoms in humans and are lethal to birds. To minimize risks, avoid overheating your nonstick pans, replace them if the coating starts to chip or scratch, and never use damaged pans. Proper care helps prevent the release of Teflon fumes and keeps you safe.

Are There Specific Brands Known for Safer Nonstick Cookware?

You can find safer nonstick cookware from brands with strong reputation and positive user reviews, like GreenPan, Caraway, and Scanpan. These brands often use ceramic or other non-toxic coatings instead of traditional Teflon. Check user reviews to verify durability and safety, and look for labels indicating PFOA-free or PTFE-free options. Choosing trusted brands helps you avoid potential risks associated with older nonstick coatings.

Conclusion

While concerns about Teflon and nonstick coatings exist, modern cookware is generally safe when used properly. You might worry about health risks, but following manufacturer instructions and avoiding high heat minimizes these issues. Plus, innovations in nonstick technology continue to improve safety and durability. So, if you stay informed and use your pans correctly, you can enjoy the convenience without compromising your health or safety.